Petroleum Gas Glass Sampling Bottles

Brand :BRT

Product origin :China

Delivery time :in 7 days after payment

Supply capacity :30 pcs / month

MTBE Pressure-proof Sample Container, Gas Chromatography Petroleum Gas Sampling Glass Bottles, ASTM D4057 LPG Inlet Sampler

High quality Petroleum Gas Sampler OEM, Supply Petroleum Gas Sample Storage Cylinders Quotes, Buy Petroleum Sampling Equipment Price

Petroleum Gas Glass Sampling Bottles(Gas Sample Storage Cylinders)

Model: BPQ

The product is also known as pressure-proof bottle and petroleum gas sampling bottle. Used for sampling and storage petroleum gas.

The product is conforming to GB/T 6012<Appearance test of industrial butadiene>; SH/T 1550<Determination of purity of MTBE- Gas Chromatography method>; GB/T 4756<Sampling Method of Petroleum liquid>.

BPQ-R model: Nylon/Nylon+Stainless steel protection 15ml

BPQ-S model: Stainless steel protection 5ml、10ml、15ml、25ml;

BPQ-B model:

Brass protection 5ml, 10ml, 15ml, 25ml;

Brass protective mesh 50ml, 100ml, 150ml, 250ml

Bottle body:95# GG17 borosilicate glass

Bottle neck:Brass Stainless steel

Bottle protection:Brass, Stainless steel, Nylon hose, Brass protective mesh

Design pressure:≤1Mpa

Structure:

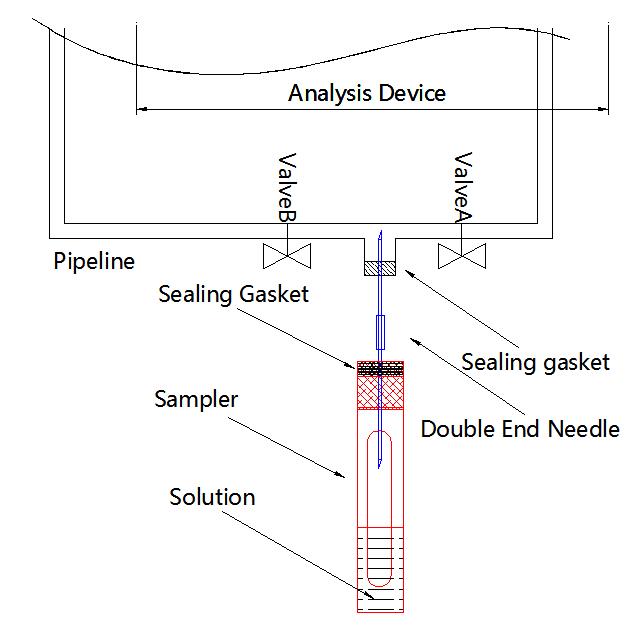

Metal protection, sampling glass tube, nut, sealing gasket. The sample operation of gas chromatograph can be realized with the needle.

Feature:

■Silicon rubber gasket and special material glass, seal pressure resistance is superior.

■The visual window is convenient for direct observation of the sample inside the bottle.

■Stainless steel/ Brass/ Nylon protector to avoid explosion hazard, safe and reliable.

■Sample pressure in sample bottle must be controlled below 1.0mpa.

Pressure Bottle Operating Instruction

Volume:5ml, 10ml, 15ml, 25ml, 30ml, 50ml, 100ml, 150ml, 250ml.

It Can also be made in accordance with the requirements

Material:Bottle body:95# or GG17 borosilicate glass

Bottleneck: Brass or Stainless steel

Protective cover:Brass or Stainless steel

Working pressure:≤1Mpa

Operating temperature:4~90℃

Structure:metal protector, sampling glass tube, screw cap, sealing gasket.

Applicable medium:MTBE, liquefied petroleum gas, butadiene, propylene ect.

Operating steps:

1. Make sure the sampler is vacancy or is filled with dissolvent by 30% volume before use.

2. Firstly, insert the double end needle one side into the sampler, meanwhile the other side insert into the interface of sample device. When the moderate samples have been collected, pull out the double end needle, then put the sampler on the shelf.

3. After sampling, the samples can be applied to analyze, test, store and view its color and state.

Notes:

1. In the process of collecting the samples, the pressure inside the bottle should be increased or decreased slowly. The sampler window should be avoid to directly face users.

2. The pressure inside the bottle must be controlled below 1.0 Mpa.