Sealed Sampling System

Brand :BRT

Product origin :China

Delivery time :in 7 days after payment

Supply capacity :30 pcs / month

Petroleum and Chemical Sealed Sampling System, Customized Equipment Line Closed Loop Sampling System, LPG Pipeline Closed Sampler

Buy Lab Sealed Sampling Device OEM, Supply Industrial Gas Cylinder Price, China Chemical Lab Sample System Factory

Sealed Sampling System (Sealed Sampler)

Model: BQM

This is a new non-leaking, pollution free sampler which is used for sampling all kinds of toxic, corrosive, explosive and flammable samples from petrochemical process pipe.

Working Temperature:-20℃~450℃

Working Pressure:0~20Mpa

We can also design and manufacture sealed sampling device to meet your special technical and safety requirements.

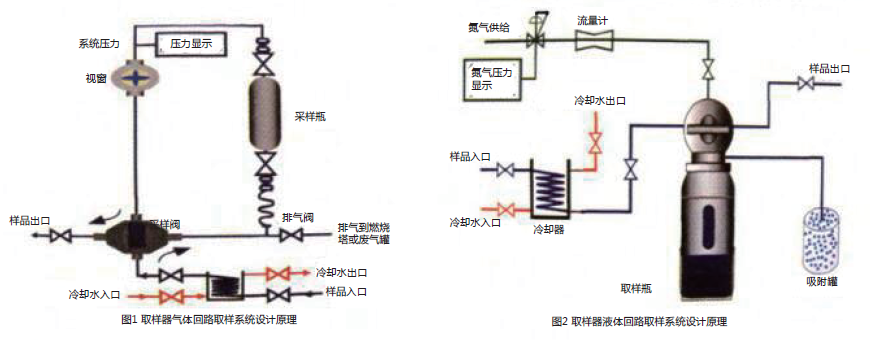

Working principle and Features:

Seamless Sampling Cylinders are suitable for gaseous media or volatile liquid media, such as liquefied petroleum gas. Both ends of the cylinder are controlled to open and close with needle valve, equipped with quick coupler, which makes the installation and removal of the sample cylinder, more safer,convenient and faster.

The non-volatile liquid medium is collected by sealed proof pressure bottle /general open bottle, excellent sealing performance and no pollution.

(1)The main body is made of 304 stainless steel, Box and surface two type Rustproof and corrosion-proof, beautiful appearance.

(2)Quick coupler between sample cylinder and process pipeline is adopted, humanized design, operation is simple and convenient.

(3)Sampling vessels: glass bottle (general open & sealed proof pressure) and sampling cylinder.

(4)Sample cylinder formed by utilizing spinning process, 316 stainless steel, smooth inner wall, corrosion resistance is nice.

(5)Collected Sample is representative and accurate, no residual liquid or gas emissions, effective to prevent the damage of toxic and harmful media to operators.

(6)According to the physical and chemical properties of the media, users can choose to add various functions to ensure the efficient, accurate and safe sampling process.

The function of quantification, heat tracing, circulation, cooling, purging, decompression, condensation, filtration can be choosed.

User shall provide effective on-site sampling media pressure, temperature, type of media and specific on-site sampling environment for us.